Excavators, wheel loaders, crawler excavators, bulldozers, backhoe loaders, etc. are special vehicles that perform heavy jobs with certain features. Operators must be properly trained and educated to the use of all the components of the machine, especially the engine, transmission, hydraulic system, electrical system, etc., and follow the safety standards defined by the legislation and by the company.

The employer is responsible for providing appropriate training for the works to be performed and all the relative safety devices related, which we showed in the following image.

Table of Contents

Main risks at work and preventive measures

The risks for the operators are multiple depending on the operations they have to perform.

- Risks associated with the initial checking of the machine

In this phase the operator can burn himself touching hot elements of the vehicle, such as engine, transmission or water, oil and fluid stopper in general.

In these cases, to avoid damage the operator will have to carry out his operations with simple precaution.

Furthermore, before starting the machine, the operator must check the functioning of the tires/chains, the engine, the electrical system and check that there are no leaks or malfunctions.

- Risks associated with the operation of the machine

During the operations of the machine, the operator takes greater risks, both for himself and for those around him. In this case the risks are: displacement from the vehicle; collision with other machines or materials, run over other workers. The preventive measures to be implemented in this phase are: to avoid moving a machine that has malfunctions or failures; proceed with caution when making reversing manoeuvres and pass carefully at the edge of an excavation.

- Risks associated with refuelling

Another delicate phase of the heavy machinery operator is that associated with the supply of fuel. In these cases, only good practices should avoid accidents, such as keeping all flammable material away from the fuel, not smoking and being prepared for the use of a fire extinguisher.

Signs that the operator does not have an adeguate training

What are the signs that show that the operator does not have properly training to work on heavy machines? Let’s see them: he has an accident or almost; it consumes too much fuel because he performs incorrect manoeuvres, he does not carry out preventive maintenance operations; he does not reach the production targets set by the company or slows them down.

In these cases, the operator is a problem for the company so it would be good that he receives the appropriate training to avoid accidents, breakdowns of the vehicles and economic losses for the company.

Advices for a safety work

The industrial sector is the one in which there are more accidents at work. To avoid them not only is a culture and a training devoted to the safety of all operators necessary, but it is also essential to provide the appropriate tools to all workers so they can operate in the most comfortable conditions possible.

The ergonomics of the machine is a word that we do not use every day, but which has a great impact on our daily work and which improves the working conditions of all workers of all sectors. In the case of the earth-moving industry, ergonomics is above all about comfort. When you spend many hours a day in a cabin, well-being is not a luxury but a necessity.

The simplest way to prevent the operator from having discomfort to adjust the seat and the controls so that he can operate inside the cabin with the greatest agility as possible.

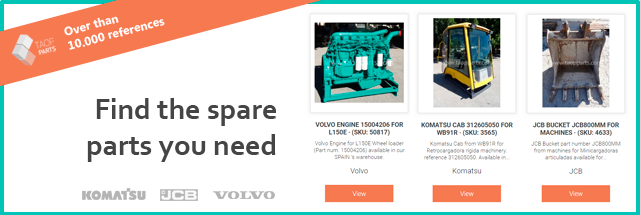

Taop Parts recommends continuous training and reminds you that thousands of used Komatsu and Volvo original spare parts are available in our warehouse, verified and ready to be shipped worldwide.

Taop Parts is the ideal partner in the maintenance of excavators, loaders, dump trucks etc, both for the quality of the spare parts sold, but also for saving in your repairs.

Links of interest:

Wow, superb blog layout! How long have you been blogging for?

you made blogging look easy. The overall look of your web site is great,

let alone the content!