The hydraulic system of a machine determines how much weight it can load and at what speed it can operate. Therefore, it represents one of the fundamental elements for the correct functioning of a wheel loader or an excavator.

In the next video we can appreciate how, thanks to the hydraulic system, the excavator’s arm and the bucket move easily.

Operators must obtain the maximum possible performance of the machines to use them in the best way and avoid wastage of fuel.

This objective can only be achieved through the implementation of a failure maintenance and prevention strategy. The checking must be carried out daily and, in the specific case of the hydraulic system, must mainly be focused on the hydraulic oil level. The filters and oil must be changed in accordance with the manufacturer’s instructions.

The hydraulic oil is in fact responsible for the operation of the whole system, so a low oil level, or a poor quality of it, leads to an increase in temperature causing the dissolution both of the oil and the other components. So, it is important to always keep in mind that heat is the enemy number one of the hydraulic system.

In fact, above 0º C the oil is dissolved, causing a reduction in the vehicle’s performance and wearing down the other elements.

Fortunately, however, today the latest generation hydraulic systems are designed to keep the oil cool during the operation of the machine.

The elements that help keep the oil at functional temperatures

Let’s see them:

- The larger the tank, the longer it takes the oil to warm up.

- The larger the cooling system, the more effective it will be in cooling the oil.

- The cooling systems must not be placed one above the other, they must be rather placed side by side to obtain the maximum cooling effect.

- The fan speed must be controlled hydraulically (not by the engine) as it is more sensitive to temperature and turns depending on its level. Moreover, in this way it does not represent a burden on the engine and consumes less fuel.

- Have a reversible fan that directs the fresh air where it is most needed.

Another problem that the hydraulic system can have, is the cavitation. Cavitation occurs when the pressure generated by the machine’s pumps causes holes in the oil. If these holes reintegrate into the pump, then they can explode and these explosions cause strong erosions in the metallic part of the pump. These explosions cannot be detected easily, but if there is a decrease in the efficiency of the pump, it is very likely that the explosions described above are the cause. Good news is that many machines manufactured in recent years are equipped with anti-cavitation oil tanks.

Another difficulty that the hydraulic system can have is in the case of leaks that decrease the oil level and certainly determine a not very efficient performance of the machine. It is important and necessary to discover the leaks and eliminate them even if this is a difficult task because these elements are all located in the lower side of the cabin and therefore difficult to reach. click on this link to be able to watch our video about the review of levels and leaks in a Komatsu WA600 wheel loader.

The operations to be carried out to control contamination

Finally, we must keep in mind that contamination can also be devastating for the hydraulic system. The contamination however is not always easily identified, in fact our technicians call it the “Ghost which haunts the hydraulic system”. To avoid contamination you have to make the following operations:

- Check the cylinder bar: normally it is from this element that contamination starts, so if the bar is scratched or damaged it will surely be easier for the contamination to reach the hydraulic system.

- Check the condition of the cylinder and of the gaskets (O-ring) that in case of bad condition can give rise to the feared leaks.

If the operator does not carry out these preventive maintenance operations, then the vehicle will lose efficiency and productivity, as well as causing the wearing and tearing of fundamental elements for its correct functioning.

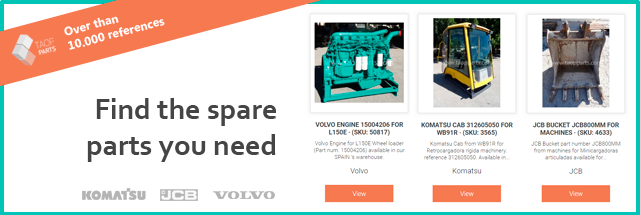

We remind you that Taop Parts has all components of the hydraulic system available, original, good use and verified by our team of experts.

LINKS OF INTEREST

Thank you for sharing your info. I really appreciate your efforts

and I am waiting for yoir next post thanks once again.

Thank you too for reading our article.

I’ll have to thank you for the success today

I am really impressed with your writing skills and also with the format to your weblog.

Is this a paid theme or did you modify it your self?

Anyway stay up the nice high quality writing, it’s rare to look a great weblog

like this one today..

Spot on with this write-up, I truly believe that this

amazing site needs a lot more attention. I’ll probably be back again to read through more, thanks for the info!

Thanks a lot for your comment. Actually we don’t need other writer, but if we need, I will contact you!

We are a gaggle of volunteers and opening a brand

new scheme in our community. Your site offered us with

useful info to work on. You have performed a formidable

task and our whole group will be thankful to you.