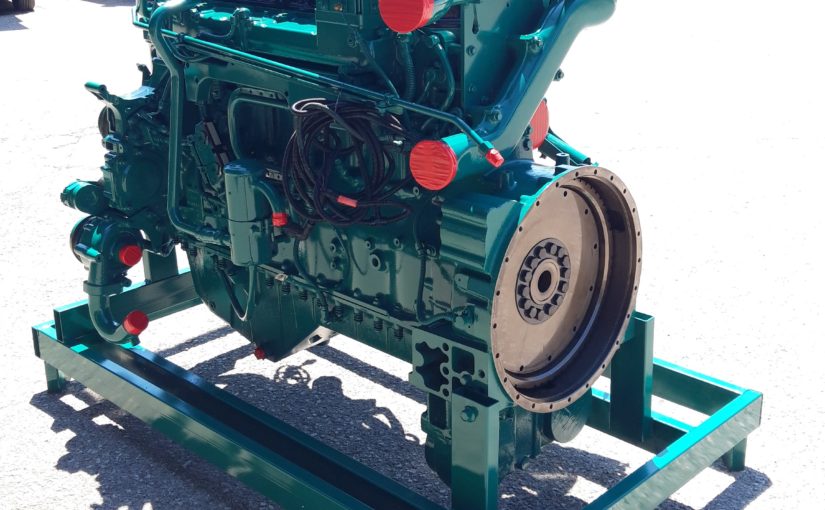

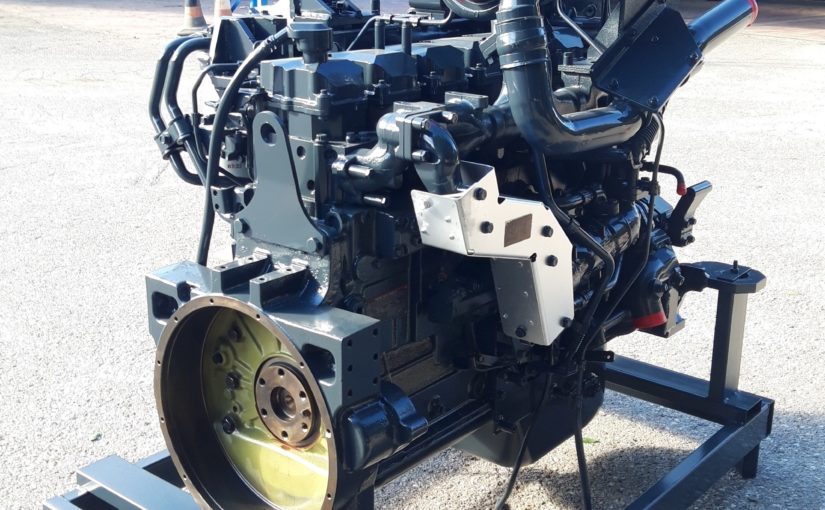

Engine timing is a crucial task to ensure optimal performance and engine longevity. In this blog, Taoparts experts will guide you through the process of tuning the Volvo D12DAAE2 engine, used in the A35D articulated dump truck. We will also discuss the specific tolerances for the intake and exhaust valves.

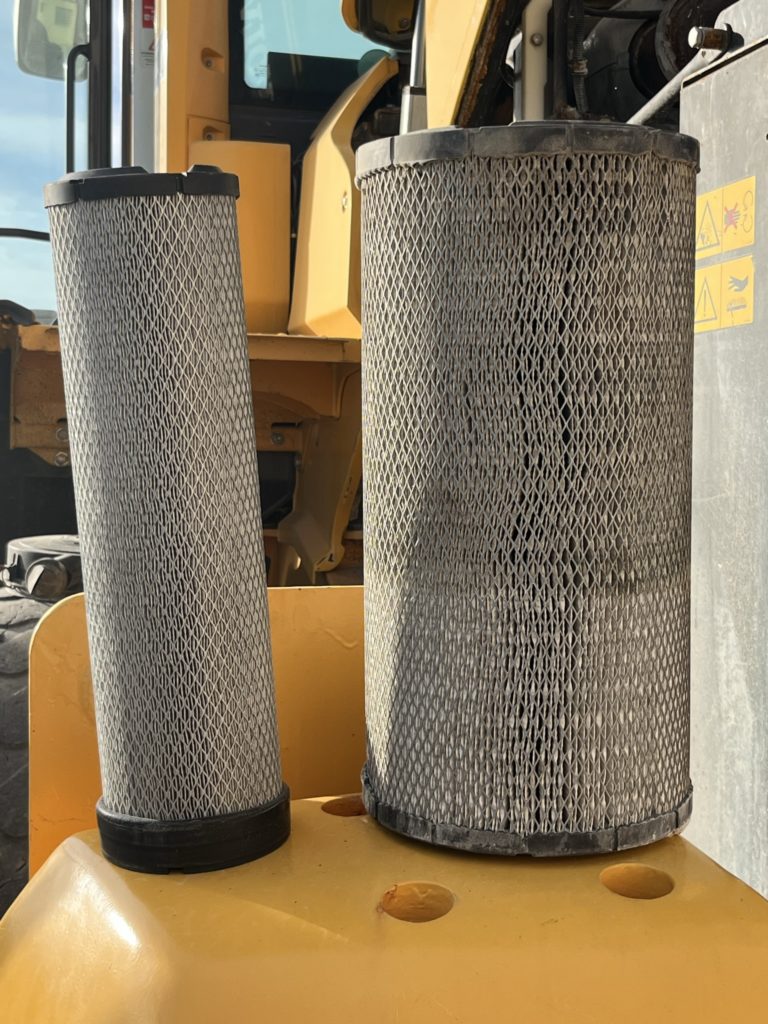

Materials Needed

- Adjustment tools (torque wrench, micrometer, valve gauge)

- Volvo D12DAAE2 engine service manual

- New engine oil and filters

- Protective gloves and glasses

Engine Tuning Steps

1. Preparation

- Disassembly: Start by disassembling the engine and making sure all parts are clean and free of debris.

- Component Inspection: Inspect engine components such as pistons, connecting rods, and rings to make sure there is no damage.

2. Adjusting the Intake Valves

- Valve Clearance: Use the valve gauge to measure the intake valve clearance. Adjust the valves to the specified tolerance of 0.2 mm.

- Check: Check the valve clearance again to make sure it is within tolerance.

3. Adjusting the Exhaust Valves

- Valve Clearance: Similar to intake valve adjustment, measure the exhaust valve clearance and adjust to the specified tolerance of 0.5 mm.

- Check: Check the exhaust valve clearance again to ensure it is within tolerance.

4. Displacement Adjustment

- Compression: Perform a compression test to ensure the engine is under proper pressure.

- Cylinder Adjustment: Adjust the cylinders to service manual specifications.

5. Assembly and Testing

- Reassembly: Reassemble the engine and replace all components that were removed.

- Functional Tests: Perform functional tests to ensure that the engine runs properly and without problems.

Conclusion

Volvo D12DAAE2 engine timing is a detailed process that requires precision and attention to detail. By following these steps and ensuring that the valves are adjusted to the specified tolerances, you can keep your engine in top condition and extend its life.

The importance of a good timing cannot be underestimated. A well-tuned engine not only ensures smooth and efficient operation, but also prevents premature component wear. By keeping intake and exhaust valves within proper tolerances, combustion is optimized and engine power is maximized, resulting in superior performance and lower fuel consumption.

Additionally, regular engine tuning is essential to detect any potential problems early. By inspecting and adjusting valves and cylinders, mechanics can identify and correct small problems before they become major failures. Not only does this save time and money on costly repairs, it also extends engine life and ensures vehicle safety.

At Taoparts, our highly trained mechanics use the most advanced tools and techniques to perform engine tune-ups with the utmost precision. We are committed to quality and customer satisfaction, ensuring that every engine that passes through our hands performs to the best of its ability.

Proper care and maintenance of your A35D articulated dump truck not only improves its performance, but also ensures that it’s ready to meet any challenges that come your way on the jobsite. Trust Taoparts to keep your equipment in top condition and maximize its efficiency and durability.

Contact us for all your spare parts needs!

Do you need spare parts for your heavy machinery? Look no further. Contact Taopparts and we will provide you with the original spare parts you need to keep your machine running at peak performance.