Efficiency is a key issue when we talk about the operation of excavators, loaders, dumpers, bulldozers, etc.

The owners of heavy machines and their operator use fewer resources to complete certain jobs than others, certainly have a competitive advantage because they use the equipments more effectively.

Scheduled and preventive maintenance, which we always recommend to be carried out regularly, is the best ally to avoid breakdowns and damage to the machine.

In this article we will deal with a very important topic, namely how to detect any contamination in the fluids present in a heavy machine.

Table of Contents

What are the fluids found in an excavator, wheel loader, bulldozer, etc?

The machines require a series of fluids for its operation. Let’s see their type:

- Hydraulic fluid

The hydraulic oil has the main function of transporting the energy into the hydraulic system, and protects, lubricates and cools the components with which it is in contact to. So, it is very important to use a hydraulic oil with a determined thermal stability and verify that it is not foamed, because this would cause an irregularity in the flow.

The contaminants of a hydraulic fluid are divided into:

– Construction contaminants: present in the components, cylinders, filters, fluids, engines and hydraulic pumps, pipes, tanks, valves etc.;

– Contaminants generated by the system: present in the components equipped with relative movements, as pumps, motors, cylinders, bearings, etc.;

– Contaminants introduced during maintenance: during disassembly and reassembly, when filling or replenishing the hydraulic fluid;

– Contaminants introduced during operation: due to leaks towards the external environment, through imperfect bleed valves, through the cylinder rods and tank openings.

- Gear fluid

The fluid for the gears allows to lubricate the moving parts reducing their wearing. For this reason, it is important that the transmission oils strictly complies with the manufacturer’s instructions.

The main risk, when talking about gears, is the so-called “pitting“, that is the superficial fatigue due to the contact pressure between the gear teeth. A phenomenon that, if not mitigated by the action of the lubricant, can smooth the teeth to make the gear at first noisy and consequently malfunctioning. One is led to think that a more viscous oil is always preferable, and part of it is true. However, a precise balance between viscosity and fluidity must be respected, because otherwise the oil tends not to remain in the gear subjected to high rotation speeds and it would thus find itself working with poor lubrication. The contaminants present in the gear oil are represented by the particles that erode the surface of the gear.

- Engine fluid

The engine oil is needed for lubricating the mechanical parts, protecting them from wearing due to friction, protecting the metal surfaces from corrosion, helping to cool the engine and creating as few residues as possible. The oil film is therefore the “shield” that protects the parts and components from harmful frictions.

The engine oil, in addition to the very important functions described above, also carries liquid pollutants (such as water or fuel) or solids (for example metal particles produced by engine wear) to the filters.

This allows the engine to operate in ideal conditions because the various contaminants – which for the engine are somewhat the equivalent of viruses for the human body – are removed from the oil, which transports them inside the filters which capture these “Viruses” and permanently remove them from circulation.

If this were not done, the engine would “get sick” in a very short time and the consequences could be disastrous – even in an extremely short time frame.

Motor oil contaminants include dust, paint, duster fibres, mechanical particles, grease, air and more.

- Coolant or cooling fluid

Cooling fluid intervenes whenever a thermostatic valve of the engine indicates overheating. Then, opens a circuit, in which this liquid is contained, whose circulation immediately cools the components. The same applies if the outside temperature drops to -40 degrees: the liquid acts as an antifreeze, releasing its fluidifying effect.

The contaminants of the refrigerant fluid consist mainly of particles, water, oil aging products and acids. Water and particles (for example iron, copper and aluminium) in fact accelerate the aging of the oil and the consumption of additives. There is a high consumption of the components with the relative increase in leaks both for machine downtime and for repairs.

- Fuel fluid

Fuel is what the machine needs to function.

The contaminants present in the diesel fuel can be of 3 types:

- Hard particles (dust, metal, rust, etc.): they cause most of the power supply system failures, damaging the surfaces of pumps and injectors, altering the fuel supply tolerances in the combustion chambers;

- Soft / resinous particles (waxes, asphaltenes, gels, etc.): they cause filter clogging and fuel oxidation;

- Liquids (water, cooling liquids, oils, etc.): they cause problems of lubricity and diesel oxidation.

What are the sources of contamination?

There are countless sources of contamination that threaten fluids in a heavy machines let’s see them:

Workshop cleaning

Contaminants can safely infest fluids if the workshop is not clean. We therefore recommend keeping the instruments and the areas where the machines are checked clean.

New oil

It will seem strange, but even a perfectly sealed oil can be a carrier of contaminants. So what we recommend is to filter it.

Operation of the machine

The normal operation of the machine produces contaminants in the system fluids because only the friction between the components produces metal contaminants.

Empty deposit

An empty deposit accumulates moisture due to condensation. We recommend always keeping the deposit full, if possible.

Benefits of contamination control

Monitor the contamination of a heart moving machine’s fluids make it possible to:

– Improve performance and extend the useful life of machine components;

– Reduce maintenance and/ or repair costs;

– Greater value of the fleet of vehicles;

– Greater safety for the operator, the machines and the surrounding environment.

Taop Parts recommends carrying out the following operations to control contamination:

– Periodically check that the gear oil does not contain particles that erode the gear surface.

– Check the temperature to carry out the work: at higher temperatures, the oxidation increases more rapidly and the oil will have a short life, also use the suitable oil for the temperature necessary to carry out the work;

– Check the oil level to see if you need to add oil or remove the obstruction.

– Take and analyze oil samples to compare its indicators with those defined by the manufacturer.

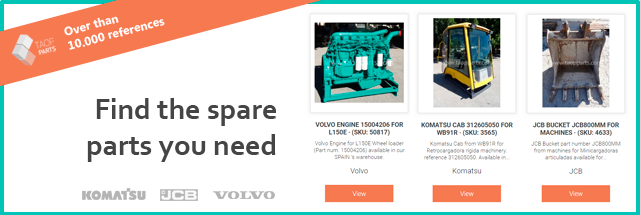

Finally, we recommend that you always use original and tested spare parts, such as those we have available in our warehouse.

Contact our commercial experts who will be happy to find the best solutions for your needs.

Links of interest:

I really like what you guys tend to be up too. Such clever work and reporting!

Keep up the great works guys I’ve included you guys to my

personal blogroll.

Superb post however , I was wanting to know if you could write a litte

more on this subject? I’d be very thankful if you could elaborate a little bit more.

Cheers!

I believe that is one of the so much important informaion for me.

Annd i am satisfied studying your article. However should remark

on few common things, Thhe site taste is perfect, thhe articles is in point of fact nice :D.

Just right activity, cheers

Your means of tellinng all in this article iis really good, all be able to simply know it, Thanks a lot.

I could not resist commenting. Well written! I couldn’t resist commenting.

Exceptionally well written! I visited several websites except the audio feature for

audio songs current at this web page is truly superb.

http://hats.com/

Wow, this piece of writing is pleasant, my sister is analyzing these kinds of things, thus I am going

to inform her.

I believe this is among the so much significant information for me.

And i’m happy studying your article. But want

to remark on some general issues, The website style is ideal, the articles is in reallity excellent : D.

Excellent job, cheers

It’s actually a great and useful piece off info. I’m glad

that you siply shared this helpful info with

us. Please stay us informed like this. Thank yoou for sharing.

I am really impressed with your writing skilpls

as well as with the layout on your weblog.

Is this a pasid theme orr did you modity it yourself?

Either wayy keep up the excellent quality writing, it iss

rare to see a great blog like this one these days.

This is really interesting, You’re a very skilled blogger.

I’ve joined your feed and look forward to seeking more

of your excellent post. Also, I have shared your web site

in my social networks!

Wow, this post is pleasant, my younger sister is analyzing these kinds of things, therefore I am going to inform her.

I’m extremely pleased to discover this page. I need to to thank you for

your time for this wonderful read!! I definitely loved every bit of it and i also have you book-marked to see new

information in your website.

“Having read this I believed it was really informative. I appreciate you finding the time and effort to put this information together. I once again find myself personally spending a significant amount of time both reading and posting comments. But so what, it was still worthwhile!”

I just want to mention I am all new to blogs and certainly enjoyed your web-site. Very likely I’m planning to bookmark your site . You absolutely have wonderful articles. Thanks a bunch for sharing with us your webpage.

Thanks for posting this awesome article. I’m a long time reader but I’ve never been compelled to leave

a comment. I subscribed to your blog and shared

this on my Twitter. Thanks again for a great article!