Keeping your Volvo L90G Loader in optimal condition is essential to ensure its performance and durability. Below are the key points you should check regularly to keep your machine in excellent condition.

What elements should we take into account?

We will list all those points to check to have your Volvo L90G loader in perfect working order.

Hydraulics and Transmission

- We will check the hydraulic system, making sure the oil is circulating properly.

- We’ll inspect the differential locking system, which is crucial to maximizing traction.

- We will ensure that the Automatic Gear Shift System (FAPS) works smoothly.

We will check the brake wear indicators.

Engine

- We will carry out an exhaustive check of the turbo diesel engine, such as checking for possible leaks in the injection system.

- We will check the fuel pump, tubes and hoses (are they free of leaks?), electrical connections of the injectors, cooled exhaust gas recirculation sensor and the particulate filter.

- We will check the aftercooler line (clamps, hoses, etc.) so that no leaks are observed. A leak can cause a drastic loss of power.

- As long as we have the necessary instruments, we will check the diesel particulate filters (DPF) and their correct operation.

Air conditioning and fuel efficiency

- We will ensure the correct operation of the air conditioning system and monitor the warning indicators.

- We will use the different work modes that the loader offers us to save fuel consumption.

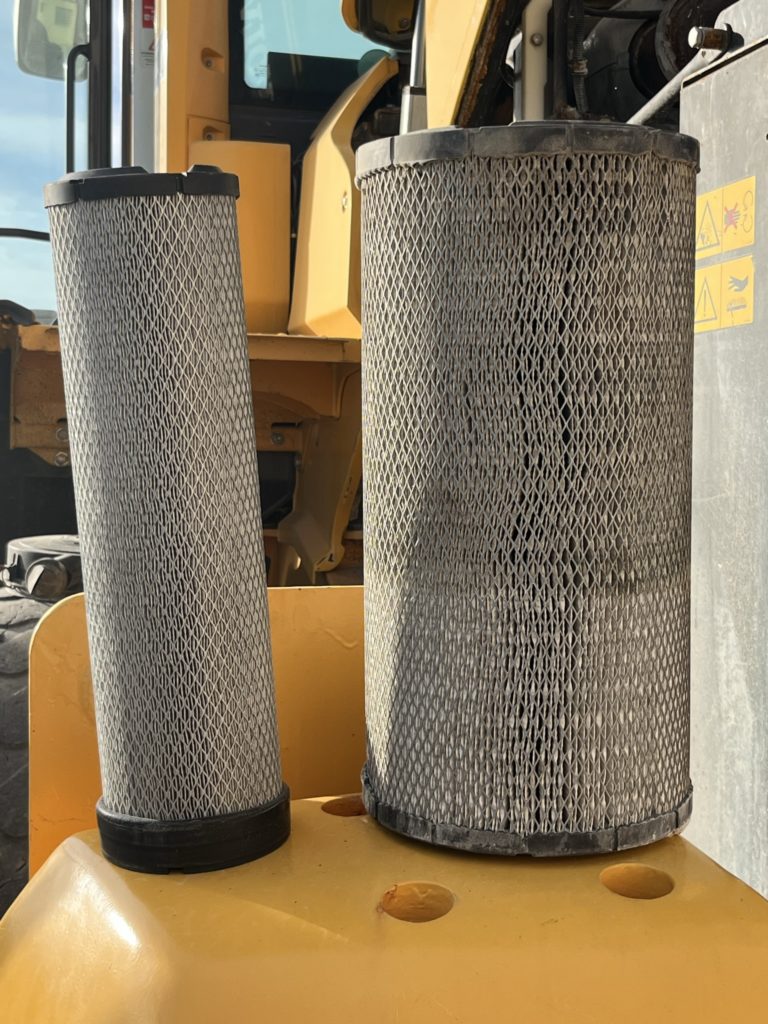

Air Filter and Hydraulic Steering

- We will inspect the air filter, both the pre-filter and the main filter, located on the top of the machine to ensure clean air flow.

- We will verify the hydraulic steering system, we will check that it is free of leaks and that its operation is correct (for example that it does not shake during its activity).

Structure and Accessories

- The axle supports are maintenance-free and designed for long life. Even so, it should be noted that the pivot shaft lubrication system works correctly.

- We will ensure that the hydraulic cooling fan is properly controlled electronically and rotates only when necessary.

- To facilitate maintenance tasks, the hood has a new design that opens electrically with a wide opening range.

Transmission and Brakes

- We will review the single lever gearbox, the valves and the automatic gear change from 1 to 4.

- We will check the brakes, including wear indicators and nitrogen accumulators.

- We also ensure that the Contronic system activates automatic declutching when braking. It is important to check, always with the machine stopped, the braking system by applying the brakes for a minimum of 30 seconds).

Cabin and Safety

- We will inspect the cabin, including monitors, heater and defroster, as well as the air vents on all windows.

- We will check the seat suspension and seat belt.

- The machine must be equipped with an emergency exit hammer to break the window if necessary.

Lifting and Hydraulics Cylinders

- The lift cylinders, hydraulic pump, valves and hydraulic control levers must be visibly free of leaks.

- We will verify the operation of the bucket positioner and the adjustable position indicator.

General Maintenance

- We will check the levels of fuel, engine coolant, hydraulic oil, gearbox oil, engine oil and axle oil.

- We will carry out regular maintenance, such as draining and filling the engine oil.

- We will check the brake lines and system connections.

Exhaust System and Electrical System

- We will check the exhaust system, especially possible sensor failures and possible intake air preheating failures.

- We will check the electrical system, which includes:

- Alternator, battery disconnect switch, batteries, hour meter, horn, instrument panel, gearbox temperature, coolant temperature and instrument lighting.

Lighting System and Outdoor Equipment

- We will check the lighting, which includes headlights, brake lights, taillights, turn signals, and halogen work lights (2 front and 2 rear).

- This model of loader comes equipped with an important safety element, such as the rear camera, which we will periodically review to verify its correct operation.

- We will check the condition of the fenders, the cabin fixings and the engine and gearbox sinemblocks. All protections must be in place.Maintaining a routine of regular inspection and maintenance of these points is essential to ensure optimal performance and prolong the life of your Volvo L90G. Follow Volvo’s recommended maintenance schedule and perform regular inspections to keep your machine in excellent condition.Do not hesitate to contact us for all the necessary spare parts for your machine atinfo@taopparts.com